Gliders

The perfect balance between performance and security.

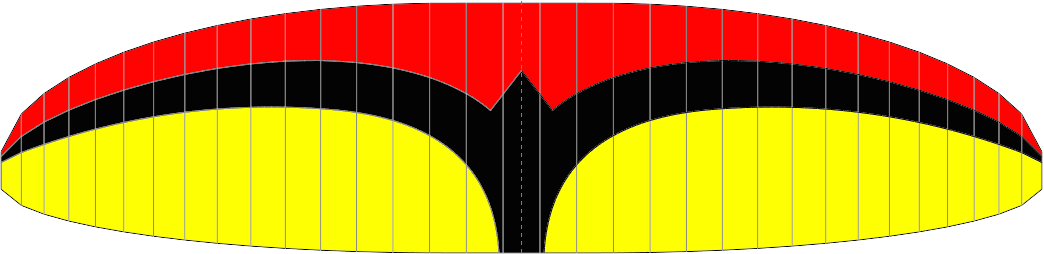

The Senso Sport has all the virtues of the Senso plus a reduction in weight of around one kilogramme.

The wing has benefitted from all our research and development for the TREK range. It boasts slightly improved performace compared to the SENSO.

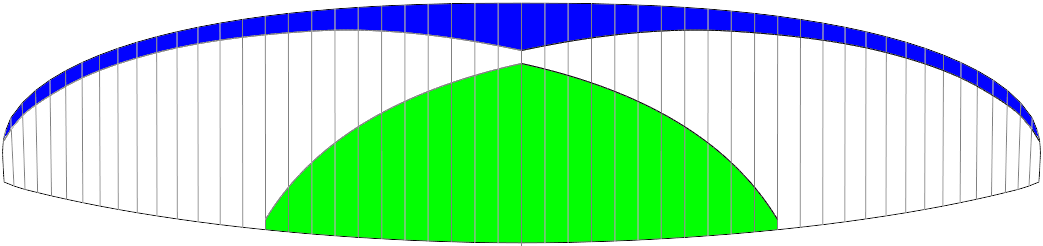

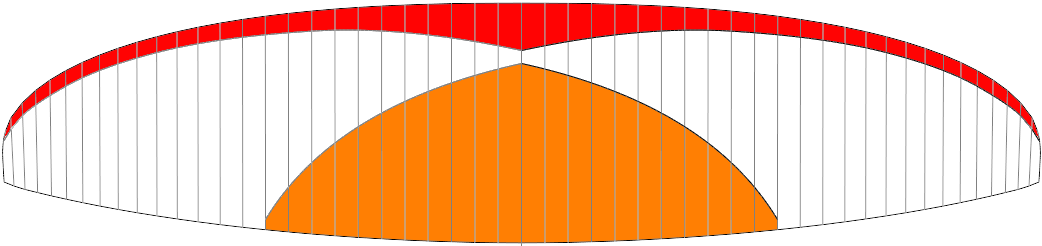

The fabric selection for different parts of the structure has been optimised for strength and lightness:

◦ Leading edge top surface in Skytex Universal 38

◦ Trailing edge top surface in Skytex Universal 32

◦ Bottom surface in Skytex 27

◦ Load-bearing ribs in Skytex 40 hard

◦ Non-Load-bearing ribs in Skytex 27 soft

◦ Diagonals in Skytex 32 hard

◦ Mykar doublers : no nylon rods

The lines are fully sheathed, but thinner in the lower section of the cascade compared to the SENSO.

◦ Dyneema 80 Kg for top section of cascade.

◦ Dyneema 100 Kg for middle section.

◦ Aramide 190 and 230 Kg for lower section.

Like the SENSO, the SENSO SPORT's porformance allows long duration and long distance flights to be accomplished without stress.

It's lighter weight makes it easier to inflate, and more reactive in flight.

It takes up less room when folded.

Impeccable build quality

◦ All fabric by Porcher Sport - the number 1 supplier in the world for paraglider fabric.

◦ All lines by Edelrid. Dyneema for top and mid section, aramide for bottom section : for durability and stability.

◦ Risers in COUSIN polyester and Aramide, sewn by robotically controlled machines.

◦ Brake line and speed system pulleys by Harken, with ball bearings.

◦ Maillons by Peguet in stainless steel. Your safety is in our materials selection.

◦ Laser cut technology, precise and durable, allows the assembly of wings with 1mm accuracy over 3m ribs!

◦ Assembly of wings using paralell double stitching

Respect for the Environment

Out of concern to reduce transport emmissions, and their associated costs, we have chosen to have 100% of our manufacturing done in Europe. The source materials are entirely European and the assembly is done in Croatia. This way of doing things is both economical and ecological.

Our range of Gliders:

High-end performance with rod reinforced shark nose

Performance without stress

Thinner lines and lighter fabric than the Senso for a sportier feel.

Ultra lightweight hike and fly

Our monosurface wing.

Go anywhere tandem

In 2017 - TREKKING presents the BIRD, a marriage of advanced technology and flying pleasure.

En 2016 - TREKKING moves manufacturing of its gliders to FRANCE.

As part of our commitment to doing business well, taking care of people and the planet.

In 2013 we made a first step by moving our production from Asia to Eastern Europe. Our aim was to reduce transport related pollution and costs.

Today we are manufacturing in France:

-

Further reduction in transport related pollution.

-

We have total control over our production process.

-

And we're contributing more to the local economy.

Local in-house manufacturing raises costs slightly overall, but our prices are still keen - 25 to 30 % less than our competitors.